HVAC high pressure switches are critical safety devices that monitor system pressure to prevent damage. They feature a manual reset function, ensuring safe operation by requiring intervention after tripping.

Definition and Purpose

An HVAC high pressure switch with manual reset is a critical component designed to monitor and control pressure levels within heating, ventilation, and air conditioning systems. Its primary function is to protect the system from damage caused by excessive pressure by interrupting operation when unsafe conditions arise. The manual reset feature ensures that the switch must be physically reset after tripping, preventing automatic restart and allowing for manual intervention to address the issue. This safety mechanism is essential for maintaining system reliability and preventing potential hazards associated with high-pressure events.

Importance in HVAC Systems

HVAC high pressure switches with manual reset play a vital role in ensuring system safety and efficiency. They act as protective devices, halting operation when pressure exceeds safe limits, thus preventing equipment damage and potential hazards. By requiring manual reset, they ensure that system issues are addressed before resuming operation, minimizing risks of recurring problems. This feature is particularly crucial in residential and commercial systems where continuous operation is essential, and unexpected shutdowns must be carefully managed to maintain comfort and functionality. Their reliability and effectiveness make them indispensable components in modern HVAC setups.

Basic Components

HVAC high pressure switches with manual reset typically consist of a pressure-sensing element, electrical contacts, and a reset mechanism. The pressure sensor detects system pressure, while the electrical contacts control the circuit. The manual reset button allows the user to restart the system after a trip. These components work together to monitor and regulate pressure, ensuring safe and efficient operation. They are designed to meet specific industry standards, offering reliability and durability in various HVAC applications. Proper installation and maintenance of these components are essential for optimal performance and system longevity.

Manual Reset Function

The manual reset function in HVAC high pressure switches ensures safety by requiring a manual intervention to restart the system after a pressure-related shutdown, preventing automatic restarts.

How the Manual Reset Works

The manual reset function on an HVAC high pressure switch operates by deactivating the switch when system pressure exceeds safe levels. Once tripped, the switch disconnects power to the HVAC system, requiring manual intervention to resume operation. To reset, press the designated reset button, typically located on the switch. This action restores the electrical connection, allowing the system to restart. The switch remains in its default state (normally open or closed) until the next pressure threshold is breached. Manual reset ensures safety by preventing automatic restarts, which could lead to further damage or hazards. Always inspect the system before resetting to identify and address the cause of the trip.

When to Use Manual Reset

A manual reset is essential in HVAC high pressure switches to ensure safe system operation. Use it after the switch trips due to excessive pressure, indicating a potential issue. Unlike automatic resets, manual resets prevent the system from restarting without addressing the underlying cause. This feature is particularly crucial in high-pressure applications where unchecked operation could lead to equipment damage or safety hazards. Always perform a manual reset only after correcting the system issue and verifying safe operating conditions. This ensures the HVAC system runs efficiently and safely, preventing further trips or malfunctions. Regular inspections and maintenance can help minimize the need for manual resets.

Advantages and Disadvantages

The manual reset function in HVAC high pressure switches offers enhanced safety by requiring human intervention to resume operation, ensuring issues are addressed. This prevents automatic restarts that could cause damage. It also provides clear indication of system malfunctions, prompting timely maintenance. However, manual resets can be inconvenient, requiring physical access and downtime. Additionally, improper resetting without diagnosing the issue may lead to recurring trips. While reliable and durable, manual reset switches may not suit applications requiring uninterrupted operation. Balancing these factors is key to selecting the right switch for HVAC systems.

Key Features of HVAC High Pressure Switches

HVAC high pressure switches feature adjustable pressure settings, manual reset functionality, and durable designs. They include SPST configurations, ensuring reliable operation and system protection against over-pressurization.

Pressure Range and Settings

HVAC high pressure switches are designed to monitor and respond to specific pressure thresholds, typically ranging between 200 to 600 PSI, depending on the application. These switches are set to trigger when pressure exceeds safe operational limits, protecting the system from potential damage. Models like the Lennox 86H3101 are set to actuate at 410 PSI, while others, such as the Supco SMR575, offer adjustable settings for flexibility. The pressure range is critical for ensuring the switch accurately detects abnormal conditions, making it essential to align the settings with the system’s operational requirements for reliable performance and safety.

Switch Type and Configuration

HVAC high pressure switches are available in various configurations to suit different system requirements. Common types include SPST (Single Pole Single Throw) and SPDT (Single Pole Double Throw), each offering distinct switching behaviors. SPST switches provide a simple on/off operation, while SPDT switches allow for more complex circuit control. Configurations may also vary between normally open (NO) and normally closed (NC) states, depending on the application. Manual reset switches, such as the Wilspec HM Series, are designed to ensure safety by requiring manual intervention to resume operation after a trip. These switches are often compatible with a wide range of pressure settings and HVAC systems, ensuring versatility and reliability in operation.

Durability and Reliability

HVAC high pressure switches are built to withstand harsh environments, ensuring long-term reliability. Many models, like the Supco SMR410, feature durable construction with high-quality materials and sealed designs to prevent contamination. These switches are engineered to handle extreme pressures and temperatures, maintaining consistent performance over time. Their robust design ensures minimal wear and tear, even in heavy-duty applications. With features like excellent set point repeatability and a life expectancy of up to 100,000 cycles, these switches provide dependable operation, crucial for maintaining HVAC system efficiency and safety. Regular maintenance further enhances their reliability, making them a trusted component in HVAC systems.

Applications in HVAC Systems

HVAC high pressure switches are essential in residential and commercial systems, monitoring pressure to protect compressors and ensure safe operation across various applications.

Residential HVAC Systems

In residential HVAC systems, high pressure switches with manual reset are essential for protecting compressors and ensuring safe operation. These switches are typically installed near the compressor and are designed to trip when pressure exceeds safe levels. Manual reset functionality requires homeowners to intervene, ensuring awareness of potential issues. Models like the Lennox 86H3101 and Supco SMR410 are popular choices, offering reliable protection. They are designed to actuate at specific PSI levels, providing a critical safety layer. Regular checks and resets can prevent system damage, making them a vital component in residential HVAC setups.

Commercial HVAC Systems

In commercial HVAC systems, high pressure switches with manual reset are crucial for safeguarding large-scale operations. These switches monitor pressure levels to prevent compressor damage and system failure. Designed for higher capacity, they are often used in industrial and large commercial settings where pressure fluctuations are more extreme. Models like the Danfoss ACB series and Johnson Controls AP5210 are popular, offering durability and reliability. Manual reset ensures that system issues are addressed before restarting, providing an additional layer of safety. Their robust construction and precise pressure settings make them indispensable in maintaining efficient and safe commercial HVAC operations.

Safety Considerations

Ensure proper installation and regular inspection of high pressure switches to prevent system overpressure. Always follow manufacturer guidelines for manual reset and emergency procedures to maintain safety.

Preventive Measures

Regular inspection of the HVAC high pressure switch is essential to ensure optimal performance. Check for wear and tear, and ensure all electrical connections are secure. Proper installation and alignment prevent premature tripping. Maintain the system’s pressure levels within recommended ranges to avoid unnecessary activations. Schedule periodic testing of the switch’s functionality and reset mechanism. Keep the surrounding area clean and free from debris to prevent interference. Always follow manufacturer guidelines for settings and maintenance. Address any issues promptly to avoid system downtime and potential safety hazards.

Emergency Procedures

In case the high pressure switch trips, immediately shut off the HVAC system’s power to ensure safety. Allow the system to cool down before proceeding. Check for any blockages or refrigerant issues that may have caused the tripping. Once the issue is resolved, press the manual reset button firmly to restore operation. Avoid repeated resets without addressing the root cause, as this can lead to further damage. If the problem persists, contact a certified technician to diagnose and repair the system. Always prioritize safety and follow manufacturer guidelines for emergency situations.

Troubleshooting the High Pressure Switch

Check for refrigerant leaks, blockages, or faulty wiring. Verify pressure settings and ensure proper system operation. Address underlying issues before resetting to prevent recurring tripping.

Common Causes of Tripping

High pressure switches in HVAC systems trip due to excessive refrigerant pressure, often caused by issues like blockages in the condenser coil, faulty fan motors, or refrigerant overcharging. Other causes include restricted air flow, malfunctioning compressors, or improper system installation. Additionally, clogged expansion valves or capillary tubes can lead to pressure buildup. In some cases, extreme outdoor temperatures or low refrigerant levels may also trigger the switch. These issues must be addressed promptly to prevent system damage and ensure safe operation. Regular maintenance and accurate troubleshooting are essential to identify and resolve underlying problems effectively.

Step-by-Step Diagnosis

To diagnose a tripped high pressure switch, first ensure the system is off and safe to inspect. Check the condenser coil for blockages or dirt, and verify fan operation. Inspect refrigerant lines for kinks or restrictions. Measure refrigerant levels and check for leaks using appropriate tools. Test the compressor and capacitors for proper function. Review system installation for any issues that may cause pressure imbalances. Use gauges to monitor pressure levels and compare with manufacturer specifications. Address any identified faults, such as cleaning coils or replacing faulty components, before resetting the switch. Always follow safety protocols during diagnosis to prevent further system damage or personal injury.

Installation and Maintenance

Proper installation ensures safe operation of HVAC high pressure switches. Regular maintenance involves cleaning, checking connections, and verifying pressure settings to prevent malfunctions and extend lifespan.

Installation Best Practices

Proper installation of HVAC high pressure switches is crucial for system safety and efficiency. Ensure the switch is mounted securely to prevent vibration and tampering. Install it in a location with easy access for maintenance. Use appropriate wiring and connections to avoid electrical issues. Always follow manufacturer guidelines for pressure settings and compatibility with your HVAC system. Test the switch post-installation to confirm proper function. Regularly inspect the switch for wear or damage. Use the correct tools for handling and ensure all safety protocols are followed during installation.

Regular Maintenance Tips

Regular maintenance of HVAC high pressure switches ensures reliable operation and prevents unexpected system shutdowns. Inspect the switch for dust, dirt, or corrosion and clean it gently. Check connections for tightness and signs of wear. Verify that the pressure settings align with the system’s requirements. Test the manual reset function periodically to ensure it operates smoothly. Replace worn or damaged components promptly to maintain performance. Keep the surrounding area clear of obstructions for proper airflow. Schedule professional inspections annually to address any potential issues before they escalate. Consistent upkeep extends the lifespan and ensures optimal functionality of the switch.

Types of High Pressure Switches

HVAC high pressure switches include normally open (NO) and normally closed (NC) configurations, SPST and SPDT switch types, each designed for specific system requirements and applications.

Normally Open (NO) vs. Normally Closed (NC)

In HVAC high pressure switches, the terms Normally Open (NO) and Normally Closed (NC) refer to the switch’s default state. NO switches remain open until activated, while NC switches are closed by default and open when triggered. In manual reset systems, NO configurations are often used to ensure safety, as they require manual intervention to restore operation. NC switches, however, may automatically reset under certain conditions. Understanding these configurations is crucial for proper system functionality and safety, especially in high-pressure scenarios where manual reset is typically required to prevent damage or hazards.

SPST vs. SPDT Switches

In HVAC high pressure switches, SPST (Single Pole Single Throw) and SPDT (Single Pole Double Throw) switches differ in their circuit control capabilities. SPST switches have two terminals, either connecting or disconnecting a single circuit, making them ideal for straightforward on/off applications. SPDT switches, with three terminals, can switch between two circuits, offering more flexibility in complex systems. SPST is commonly used for its simplicity and reliability in high-pressure scenarios, while SPDT is preferred when multiple operational modes are required. Both configurations ensure safe and efficient system operation, tailored to specific HVAC needs.

Brands and Models

Popular brands include Supco, Johnson Controls, and Lennox, offering models like SMR410 and 86H3101, known for reliability and performance in HVAC systems with manual reset functionality.

Popular Brands

Leading manufacturers like Supco, Johnson Controls, and Danfoss offer high-quality HVAC high pressure switches with manual reset functionality. Supco models such as SMR410 and SMR375 are known for their durability and high-pressure handling. Johnson Controls provides switches like AP5208-30 and AP5210-30, catering to different system requirements. Danfoss offers the ACB series, designed for precise pressure control. Additionally, brands like Lennox and Wilspec deliver trusted solutions, with models like Lennox’s 86H3101 and Wilspec’s HM Series gaining industry recognition; These brands ensure reliable performance and safety in HVAC systems.

Model-Specific Details

Supco SMR410 offers a manual reset feature and operates at a high pressure range, making it ideal for HVAC systems. Danfoss ACB-2UB121MW is another notable model, providing precise pressure control with a manual reset option. Lennox 86H3101 is designed to actuate at 410 PSI, ensuring system protection with its manual reset capability. These models are built for durability and reliability, meeting the demands of both residential and commercial HVAC applications. Their specifications ensure safe and efficient operation, making them preferred choices among technicians and system designers.

How to Reset the High Pressure Switch

Turn off power, locate the switch near the compressor, press and hold the reset button until it clicks, then restore power to test the system.

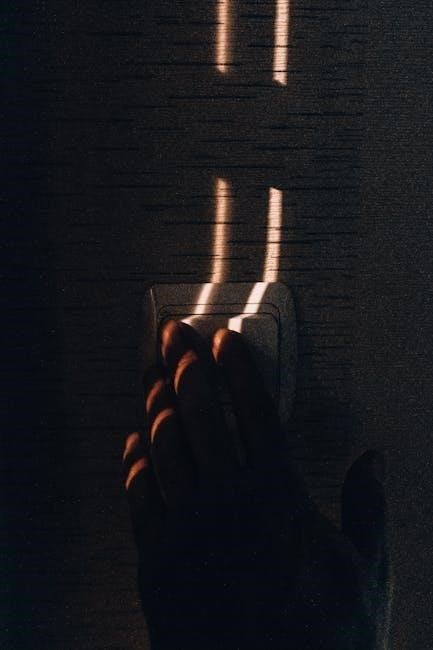

Step-by-Step Reset Guide

To reset an HVAC high pressure switch with a manual reset, follow these steps:

- Turn off the HVAC system and disconnect power at the breaker box for safety.

- Locate the high pressure switch, typically near the compressor in the outdoor unit.

- Press and hold the reset button until it clicks, indicating the switch has been reset.

- Wait a few minutes to allow the system to stabilize before turning the power back on.

- Monitor the system for proper operation and check for any recurring issues.

This procedure ensures safe and effective resetting of the switch.

Post-Reset Checks

After resetting the high pressure switch, verify system operation by turning the HVAC system back on.

- Check the system’s pressure levels to ensure they are within the normal range.

- Monitor for unusual noises or vibrations that may indicate underlying issues.

- Ensure the condenser fan is functioning properly to prevent overheating.

- Verify that the reset button remains engaged and the system operates smoothly.

These checks help confirm that the reset was successful and the system is functioning correctly.

Testing the High Pressure Switch

Testing the HVAC high pressure switch involves verifying its activation points, ensuring it trips correctly, and checking the manual reset function with appropriate tools for safety and accuracy.

Tools and Equipment Needed

To test an HVAC high pressure switch with a manual reset, essential tools include a multimeter for electrical checks, a pressure gauge to measure system pressure, and screwdrivers for accessing the switch. Pliers may be needed for wiring connections, and safety gear like gloves and goggles is recommended. A vacuum pump or manifold set can assist in diagnosing pressure issues. Ensure all tools are calibrated and suitable for high-pressure systems. These tools help verify proper function, identify faults, and ensure safe operation during testing and maintenance. Always follow safety protocols when handling electrical and pressurized components.

Step-by-Step Testing Procedure

Begin by ensuring the HVAC system is powered off and the manual reset button is disengaged. Connect a multimeter to the switch terminals to measure electrical continuity. Activate the system and monitor pressure using a pressure gauge. If the switch trips, verify the pressure reading against its setpoint. Use a vacuum pump to simulate low-pressure conditions and observe the switch’s response. Check for any electrical faults or wiring issues. Repeat tests under varying pressures to ensure reliability. Finally, reset the switch and confirm normal system operation. Document all findings for further analysis or maintenance scheduling.

Common Issues and Solutions

Common issues include recurring tripping due to high pressure or faulty switches. Solutions involve checking pressure levels, replacing worn-out switches, and ensuring proper wiring connections.

Recurring Tripping Issues

Recurring tripping of HVAC high pressure switches often indicates underlying system problems. Common causes include improper installation, blocked airflow, or refrigerant leaks. If the switch trips repeatedly, it may signal faulty pressure settings or a malfunctioning switch itself. Regular maintenance, such as cleaning condenser coils and checking refrigerant levels, can help prevent these issues. Ensuring proper system balance and addressing any leaks promptly are crucial to avoid recurrent tripping. If problems persist, professional inspection and repair may be necessary to ensure safe and efficient HVAC operation.

Wiring or Connection Problems

Wiring or connection issues can disrupt the functionality of HVAC high pressure switches. Loose connections or damaged wires may prevent the switch from resetting properly or cause false tripping. Corrosion or wear on terminals can also lead to intermittent operation. Ensuring secure, clean connections and inspecting wires regularly is essential. If a switch fails to reset due to wiring problems, it may require professional attention to avoid system damage. Proper installation and maintenance of electrical components are critical to ensure reliable operation and safety of the HVAC system.

Regulations and Standards

HVAC high pressure switches must comply with industry standards like ASHRAE and UL certifications, ensuring safety and performance. Adherence to these regulations is mandatory for system approval.

Industry Standards

HVAC high pressure switches must comply with industry standards to ensure safety and reliability. Standards like UL (Underwriters Laboratories) and ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) dictate performance and safety requirements. These standards ensure switches can handle extreme pressures and operate reliably in various environments. Compliance with these standards is crucial for system safety and efficiency, guaranteeing switches meet rigorous testing and certification processes. Popular brands like Supco and Johnson Controls adhere to these standards, offering reliable solutions for HVAC systems. Always verify compliance with industry standards when selecting or installing high pressure switches.

Compliance Requirements

Compliance with regulatory requirements is essential for HVAC high pressure switches. These switches must meet specific codes and standards to ensure safe and efficient operation. Regulations often require switches to have certifications from recognized bodies, ensuring they meet safety and performance criteria. Additionally, compliance involves proper installation and regular maintenance to uphold safety standards. Non-compliance can lead to system failures or safety hazards. Always ensure that the switch meets local and national regulations, and that installation follows all applicable guidelines. This ensures reliability and safety in HVAC systems.

HVAC high pressure switches with manual reset are vital for system safety and efficiency. Proper understanding and maintenance ensure reliable operation, protecting equipment and ensuring compliance with regulations.

The manual reset function in HVAC high pressure switches is a critical safety feature designed to protect systems from overpressure. Unlike automatic resets, manual resets require intervention, ensuring intentional activation. Popular models like the Supco SMR410 and Lennox 86H3101 offer reliable performance. These switches typically activate at set points, such as 410 PSI, and must be manually reset after tripping. Their durability and repeatability ensure consistent operation. Understanding their operation is essential for safe and efficient HVAC system management, preventing potential damage and maintaining optimal performance.

Final Thoughts

HVAC high pressure switches with manual reset are indispensable for system safety and efficiency. Their role in preventing overpressure scenarios cannot be overstated. By requiring manual intervention, these switches ensure that operators are aware of potential issues before resuming operation. Models like the Supco SMR410 and Lennox 86H3101 demonstrate high reliability and durability. Regular maintenance and understanding of their function are crucial for optimal performance. Investing in quality switches and adhering to best practices ensures long-term system reliability and safety, making them a vital component in modern HVAC systems.